We understand why some folks feel trapped by the mudlogging equipment rental game. After paying those rental companies upwards of $3000 per month, per unit, there is that feeling of, “there has got to be a better way.” What if you owned your equipment outright? You could be putting all of that money into expanding your business or paying yourself more.

New Financing Options

We at Geospect have some great new financing options available that can help you own your equipment; In most cases for a much less per month cost. In fact, if you paid your regular rental fees as a per month payment, your equipment would be paid off in as little as seven months. Isn’t it time to do this for yourself and your company?

Volume Discounts

Ask about our volume discounts when purchasing three or more

instruments. When we save money on the purchase of instrument hardware

and components we like to pass that savings on to our customers.

Why owning a Geospect Mudlogging System is a good investment for your mudlogging company.

What is Geospect

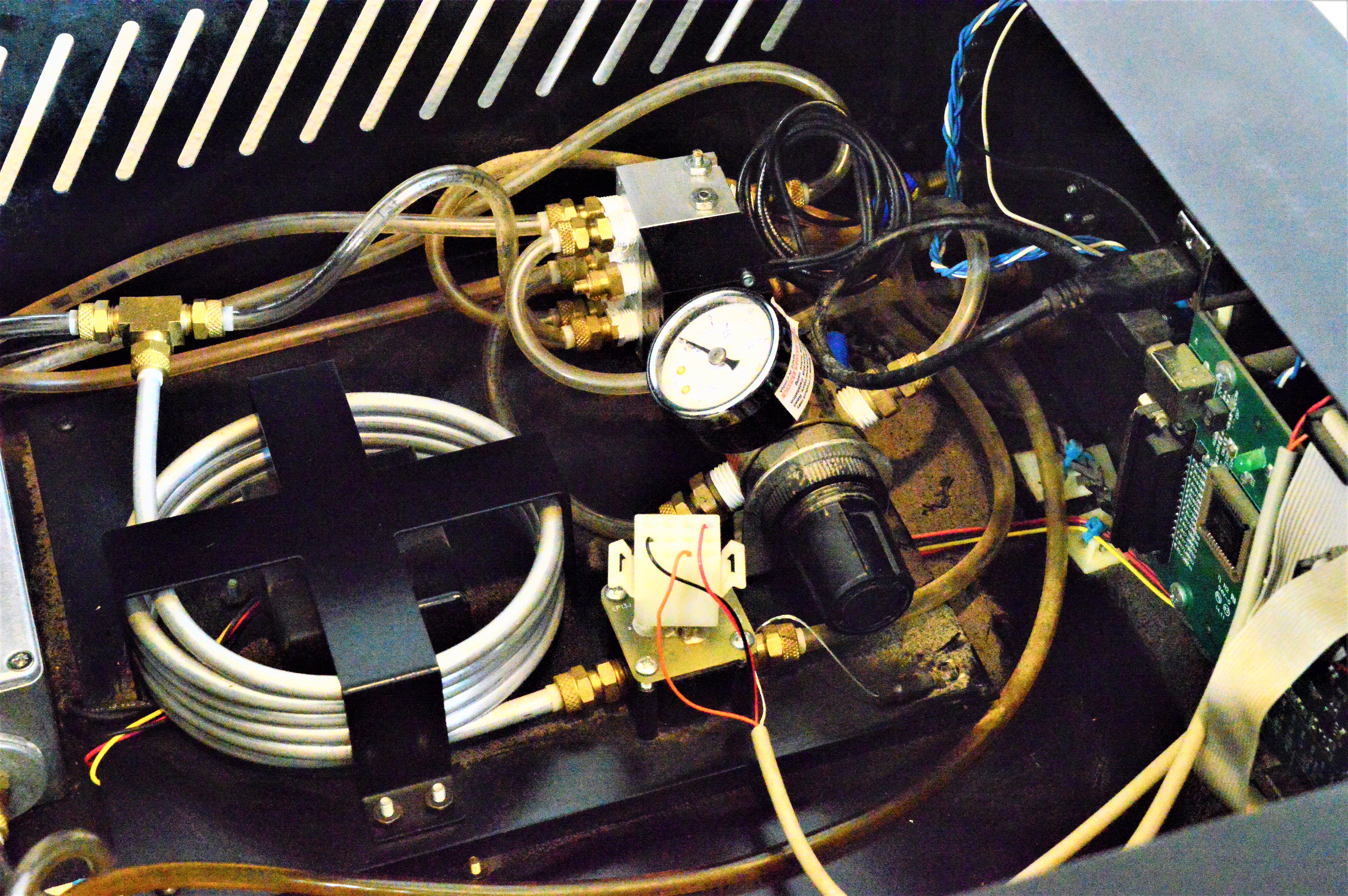

Geospect is a complete mudlogging instrumentation package. It includes

everything you need to analyze and detect gas. It has sensor inputs for

depth, pump stroke counters, and on/off bottom status. It’s powerful

software takes the sensor or WITS readings, analyze them, and display

them, and saves them in real time with incredible accuracy.

WITS

In WITS mode, Geospect communicates with other computers around the

location. Geospect seamlessly receives data and transmits gas readings

to the rig EDR (eg. Pason). This saves the mudlogger time because data

like depth and pump strokes are transmitted to Geospect automatically.

This eliminates the chore of rigging up these sensors to Geospect

separately.

The ability to transmit gas to other workstations around the location is becoming an important safety consideration to many oil companies.

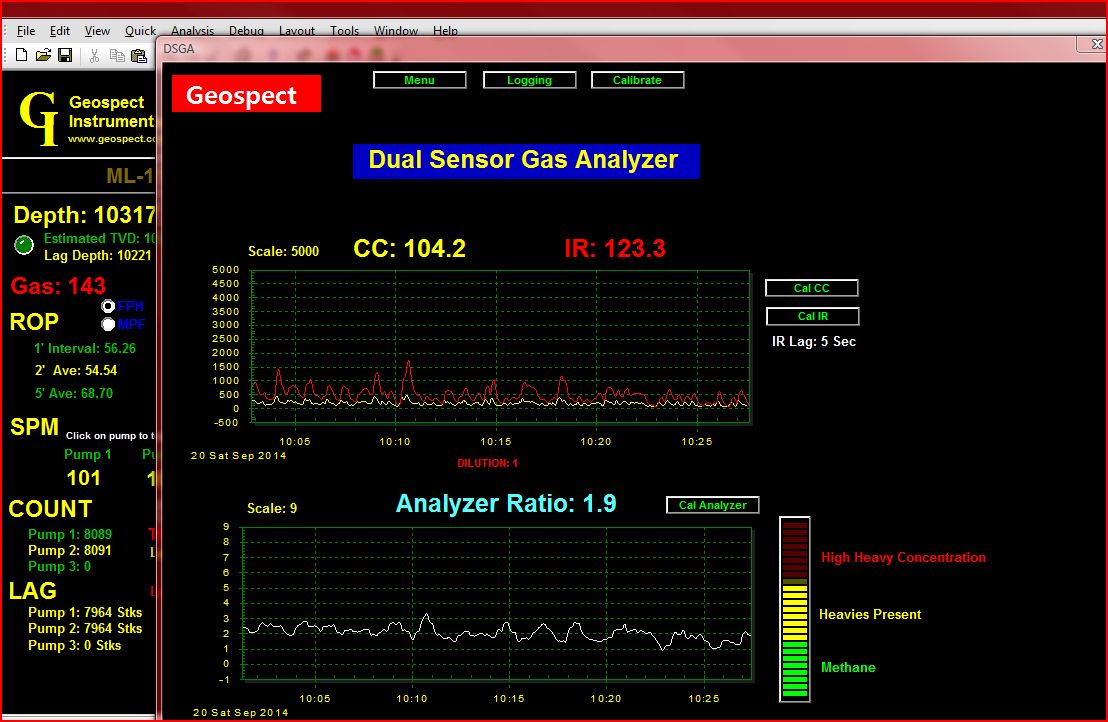

Geospect Software

Geospect software is the best in the business. It takes sensor readings and WITS data and transforms that data into useful mudlogging information. It displays mudlogging information on rich, robust, graphs and charts. The software was among the first to display a Lag Depth right onscreen. This allows the mudlogger to have all of the data he/she needs organized in one place so when asked a question the mudlogger can respond instantly and with confidence.

Screenshot of Geospect Software

Features

Geospect software is packed with many useful features. Below is a very

short list of what we believe are some of the most important ones.

- EASY SETUP

- DISPLAYS REAL-TIME CHARTS AND GRAPHS

- CALCULATES AND DISPLAYS LAG DEPTH LOGS ALL PERTINENT MUDLOGGING DATA

- IN SPREADSHEET FORMAT SEND GAS TO OTHER COMPUTERS ON LOCATION USING

- WITS RECEIVE DEPTH AND PUMP STROKES FROM RIG EDR (PASON, TOTCO …ETC.)

- HOOKS UP TO MOST MUDLOGGING SENSORS

- CHOOSE FROM TWO TYPES OF GAS DETECTORS

- ADD SOFTWARE TO 3RD PARTY GAS DETECTORS

- ADD A CHROMATOGRAPH OR CO2 DETECTOR

How Owning a Geospect Mudlogging System Saves You Money

We sell our instruments rather than rent them. For this reason our

customers can own their equipment outright and not have to pay

continuously high rental prices. In most cases a Geospect customer will

have their system paid for in as little as seven months by using the

savings from not renting equipment from one of our competitors. Wouldn’t

it be nice not to have those outrageous equipment rental bills?

How to Purchase a Geospect Mudlogging System

If you would like to purchase a new Geospect Mudlogging System, or

simply have a few questions I invite you to call us. We are always ready

to answer your questions and place orders. Also, you can visit our

website at www.geospect.com. If you would like to request a quote click here. Finally, feel free to email me directly at mike@geospect.com.